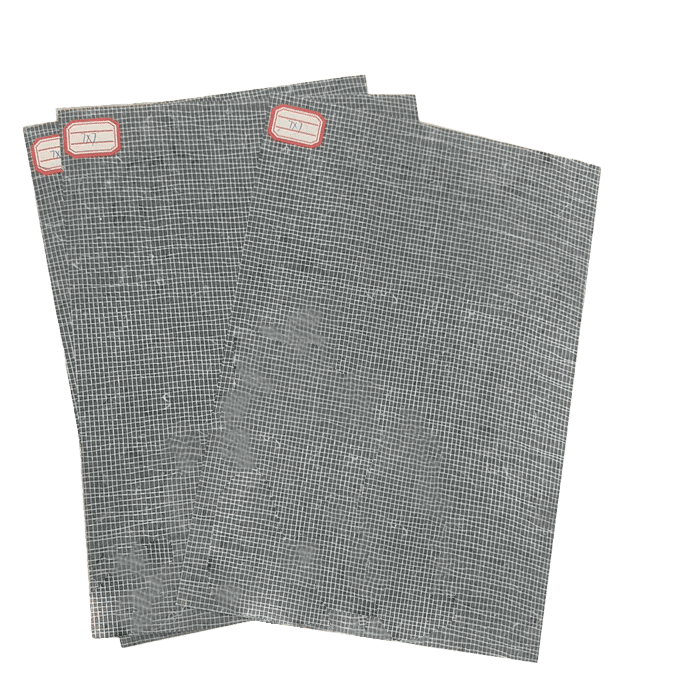

Choosing the right materials is half the battle in effective waterproofing. Compound asphalt felt base mats are increasingly used as a high-performance base sheet in both new builds and retrofits. Here’s a practical guide on how to choose, apply, and maintain this essential waterproofing layer.

1. Choosing the Right Type

Not all base mats are created equal. When selecting one, consider:

-

Reinforcement Type: Polyester mats are more flexible; fiberglass offers better dimensional stability.

-

Thickness and Weight: Thicker mats typically provide better durability and puncture resistance.

-

Coating Compound: Look for SBS or APP-modified asphalt for enhanced performance in hot or cold climates.

2. Application Techniques

Compound asphalt felt base mats can be applied via:

-

Torch-On Method: Common in roofing; requires skilled labor and safety measures.

-

Self-Adhesive Systems: Ideal for enclosed or sensitive areas where open flame is not permitted.

-

Hot-Mopped or Cold-Applied Adhesives: Suitable for large horizontal surfaces like foundations or decks.

Best Practices:

-

Ensure substrate is clean and dry before installation

-

Overlap seams appropriately (usually 75–100 mm)

-

Use proper primers and edge sealants for long-term performance

-

Always follow manufacturer’s guidelines

3. Maintenance and Inspection

-

Inspect for blisters, punctures, or seam separations at least annually

-

Repair any damage with compatible patching materials

-

Maintain proper drainage to reduce hydrostatic pressure and ponding

4. Common Mistakes to Avoid

-

Skipping surface prep

-

Installing during wet or freezing conditions

-

Not allowing for thermal expansion

Conclusion

Compound asphalt felt base mats offer reliable and long-lasting waterproofing when installed correctly. By understanding the material’s characteristics and following best practices, you can significantly extend the life of your waterproofing system.