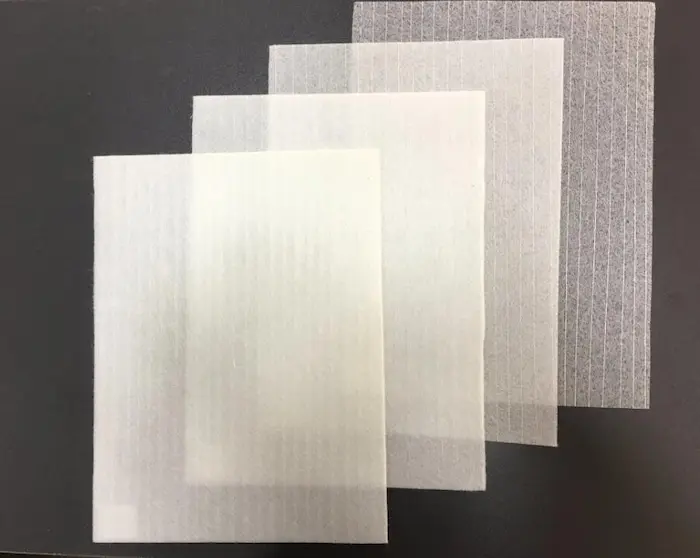

Reinforced spunbond polyester mat is a nonwoven fabric made from continuous polyester filaments, reinforced with glass fiber scrim or yarn for enhanced strength, primarily used as a substrate in APP or SBS modified bitumen waterproof membranes.

Key Properties

This material combines polyester’s flexibility with glass fiber’s stability, offering high tensile strength (e.g., MD: 400-800 N/5cm, CD: 250-580 N/5cm depending on weight), tear resistance, and heat resistance up to 150°C or more. It provides low elongation (18-33%), dimensional stability, and no shrinkage during high-speed bitumen processing, extending membrane lifespan.

Common Applications

Serves as a base layer for waterproofing roofs, roads, and shingles, improving runnability on production lines and reducing post-installation width shrinkage on slopes. Available in weights from 105-300 g/m², with widths around 1-1.2m.

Production and Benefits

Manufactured via spunbond, needling, and thermal bonding from virgin PET chips, often with longitudinally oriented glass filaments (e.g., 100/meter) for warp-directional reinforcement. Benefits include faster machine speeds, better bitumen adhesion, and eco-friendly recyclability compared to standard polyester mats