Description

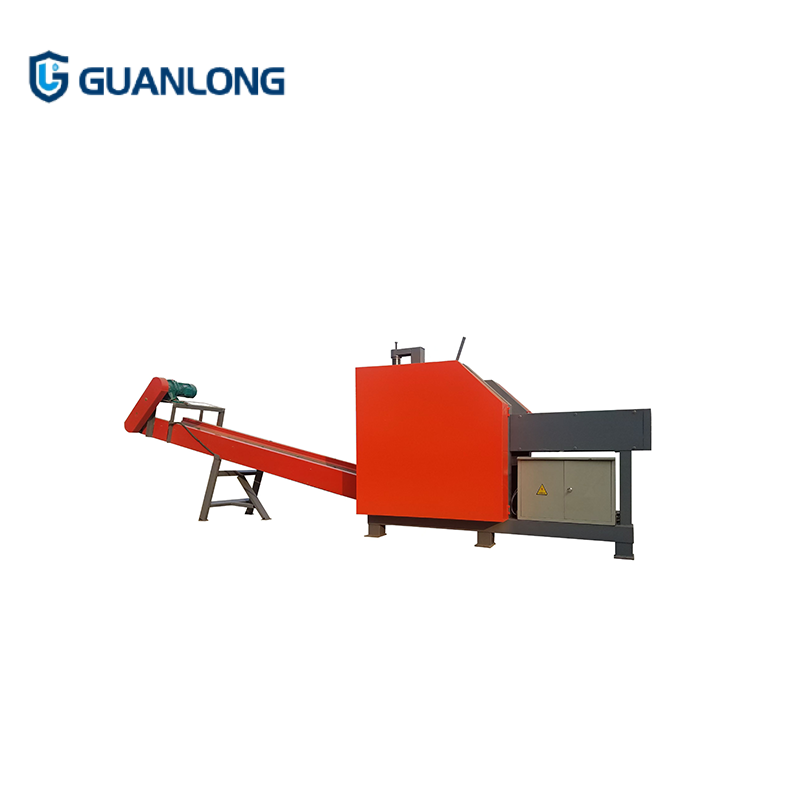

Product Description:

A Cutting Machine is an industrial equipment designed to cut various materials—such as fiber, fabric, plastic film, paper, rubber, or composite sheets—into desired sizes or shapes. It is widely used in textile, packaging, waterproof materials, nonwoven, plastic, and construction material industries.

Key Features:

-

High Precision Cutting: Ensures accurate and consistent dimensions.

-

Customizable Blade Types: Rotary blades, guillotine cutters, hot knives, or ultrasonic blades based on application.

-

Adjustable Speed & Length: Cutting length, width, and speed can be set according to production needs.

-

Multi-Material Compatibility: Suitable for polyester mat, fiberglass, PVC membrane, felt, paper, etc.

-

Durable Structure: Built with robust steel frame and wear-resistant components for long-term use.

-

Automation Options: Available with PLC control, touchscreen operation, and automatic feeding systems.

-

Safety Protection: Emergency stop, protective covers, and overload protection for safe operation.

Typical Applications:

-

Nonwoven & Textile: Polyester mat, fiberglass mat, geotextile rolls

-

Waterproofing Materials: SBS/APP membrane base mat, self-adhesive membranes

-

Plastic & Films: PET/PP rolls, PE foam sheets, PVC tarpaulin

-

Packaging & Printing: Paper, cardboard, labels

-

Construction Materials: Foam boards, insulation sheets, composite membranes

Technical Specifications (Typical):

| Item | Specification Range |

|---|---|

| Cutting Width | 500–2500 mm (customizable) |

| Cutting Length | 10–9999 mm (programmable) |

| Cutting Speed | 10–100 cuts/min (depending on material) |

| Power Supply | 220V/380V, 50Hz/60Hz |

| Blade Type | Rotary / Guillotine / Hot Knife / Saw |

| Control System | Manual / PLC Automatic with Touchscreen |

| Feeding System | Roller or Conveyor (optional) |

Optional Features:

-

Auto blade sharpening

-

Servo motor positioning

-

Dust collection system

-

Material aligning & edge guiding

-

Tension control for roll materials

The parameter list is provided

|

Device name |

Cutting machine |

Model number |

GL-800 |

|||

| Fittings materials |

Model number |

Quantity |

Remarks for wearing parts |

|||

| 1 | Shear motor | With an 8P11kw motor | ||||

| 2 | Conveyor motor | 4P2.2kw variable frequency | ||||

|

3 |

Reducer Model

No. |

XWD4 |

||||

|

4 |

Reducer speed ratio |

17:1 |

||||

| 5 | Blade width | 800mm | ||||

| 6 | Cutter material | 55SiCr/Cr12MoV/6542 | ||||

| 7 | Input tape | 1800*830mm | ||||

|

8 |

Output with motor |

4 p1.5kw |

||||

| 9 | Output band | 3000*520mm | ||||

|

10 |

Cut size |

Variable frequency

adjustable |

||||

| 11 | Shear speed | 120 times/min | ||||

|

12 |

Main frame dimensions |

2350*1500*1750mm |

||||

|

13 |

Include output tape if required |

3000*520 |

Cut size:5-8cm |

|||

| 14 | Machine weight | 2000kg | Hourly yield:1500KGS | |||

Why Choose Weifang Guanlong Waterproof Material Co., Ltd.?

✔ Specialist in Waterproof Base Materials.

We focus on producing and exporting high-quality compound base mat, spunbond polyester mat, fiberglass mat, polyester felt, and filament polyester mat—key materials for waterproofing membrane production.

✔ Complete Product Range.

From bitumen felt base mats to compound mats, we offer a full portfolio of nonwoven and composite materials widely used in SBS/APP modified bitumen membranes.

✔ Advanced Production Lines

Our factory operates modern compound base mat production lines and equipment for bitumen waterproof membrane machines, ensuring consistent quality and efficient output.

✔ Reliable Export Experience

We serve customers across Asia, the Middle East, and Europe with stable supply, competitive prices, and customized packaging.

✔ Technical Support & Customization

We offer technical advice, material selection guidance, and support for special product specifications to meet diverse customer needs.

Contact Us

Weifang Guanlong Waterproof Material Co., Ltd.Your reliable partner for high-quality materials and professional support.

📞 Phone/WhatsApp: +86 18263668883

🌐 Website: glwaterproof.com/product/

📧 Email: guanlinguoji@126.com