1. Production Flow: From Raw Materials to Finished Product

Raw Material Preparation

Compound Base Mats typically combine fiber substrates such as fiberglass or polyester with cotton fibers or nonwoven webs. These raw materials are carefully selected based on the intended strength, flexibility, and application requirements.

Layer Formation and Composite Structure

The manufacturing starts by laying down cotton or polyester fibers uniformly onto a conveyor system, forming a base layer. This layer is then coated or impregnated with a starch-based adhesive or binder to improve bonding between layers.

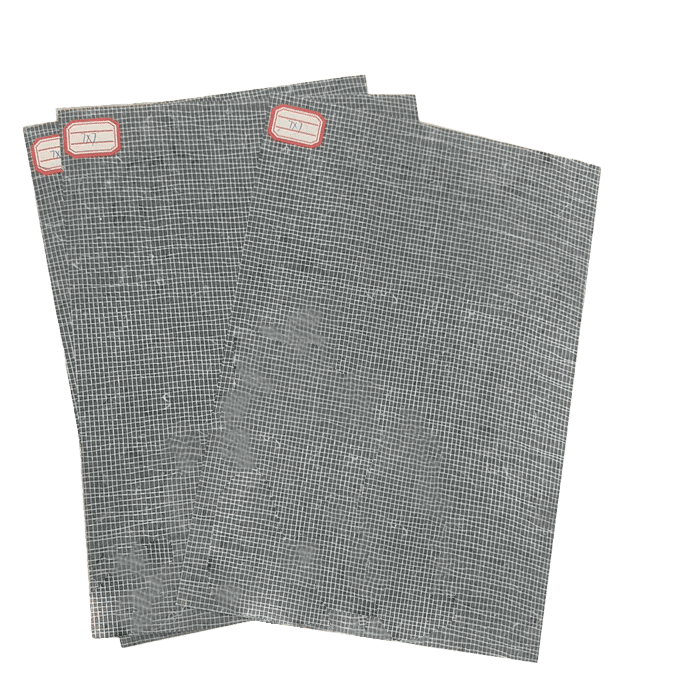

Adding Reinforcement Layers

On top of the fiber base layer, a reinforcing mesh such as fiberglass or polyester net is added. This significantly enhances tensile strength, dimensional stability, and durability of the mat.

Drying and Curing

The composite mat is passed through drying ovens to remove moisture and cure the binder, stabilizing the structure. Controlled temperature and drying time ensure the mat maintains its shape and mechanical properties without warping.

Cutting, Rolling, and Packaging

Finally, the mats are trimmed to specified widths, rolled up, and packaged for shipment. Fully automated production lines enable continuous and high-volume manufacturing with consistent quality.

2. Key Process Parameters Affecting Material Performance

-

Fiber Type and Blend Ratio

The choice between fiberglass, polyester, cotton, or blends affects strength, moisture absorption, and cost. Fiberglass offers high tensile strength, whereas polyester or cotton improves flexibility and workability. -

Binder Composition and Application

The type and amount of starch or adhesive impact inter-fiber bonding and overall mat cohesion. Proper impregnation ensures durability and resistance to delamination. -

Layer Thickness and Density Control

Uniform fiber distribution and density are critical. Thicker or denser mats generally improve durability but may reduce flexibility. -

Drying Temperature and Duration

Optimizing drying prevents thermal degradation and distortion. Excessive heat can weaken fibers; insufficient drying leads to poor binder curing. -

Automation and Process Control

Modern lines use precise control systems to regulate fiber feeding speed, binder dosing, drying parameters, and winding tension, ensuring product uniformity and reducing waste.

3. Latest Manufacturing Technologies and Innovations

-

Eco-friendly and Sustainable Materials

There is growing adoption of recycled fibers, bio-based binders, and natural fillers to lower environmental impact. Incorporating agricultural by-products like bamboo powder or rice husk into the mat structure offers improved sustainability without sacrificing performance. -

Advanced Automation and Smart Manufacturing

Integration of sensors, real-time monitoring, and data analytics optimizes energy consumption, enhances process stability, and facilitates predictive maintenance, boosting efficiency and reducing downtime. -

Emerging Composite Techniques

Although still in development, multi-layer co-extrusion and compression molding techniques from broader composite manufacturing sectors hold potential for producing mats with tailored multi-functional properties, such as improved thermal insulation or fire resistance.

Conclusion

The manufacturing of Compound Base Mats involves a complex interplay of material selection, layer composition, binder chemistry, and precise process control. Controlling key parameters like fiber type, binder application, and drying conditions is crucial for achieving the desired performance. Advancements in sustainable materials and smart automation are driving the industry toward significant innovation, balancing performance, cost, and environmental responsibility.

If you want to explore specific aspects like material innovations or production equipment details, feel free to ask!

Contact Us

Weifang Guanlong Waterproof Material Co., Ltd.Your reliable partner for high-quality materials and professional support.

📞 Phone/WhatsApp: +86 18263668883

🌐 Website: glwaterproof.com/product/

📧 Email: guanlinguoji@126.com