The substrate beneath a waterproofing membrane plays a crucial role in the overall performance and durability of roofing waterproofing systems. Selecting the right substrate material is essential to prolong the lifespan of the waterproof membrane and ensure reliable protection against moisture intrusion.

1. Understanding the Role of the Substrate

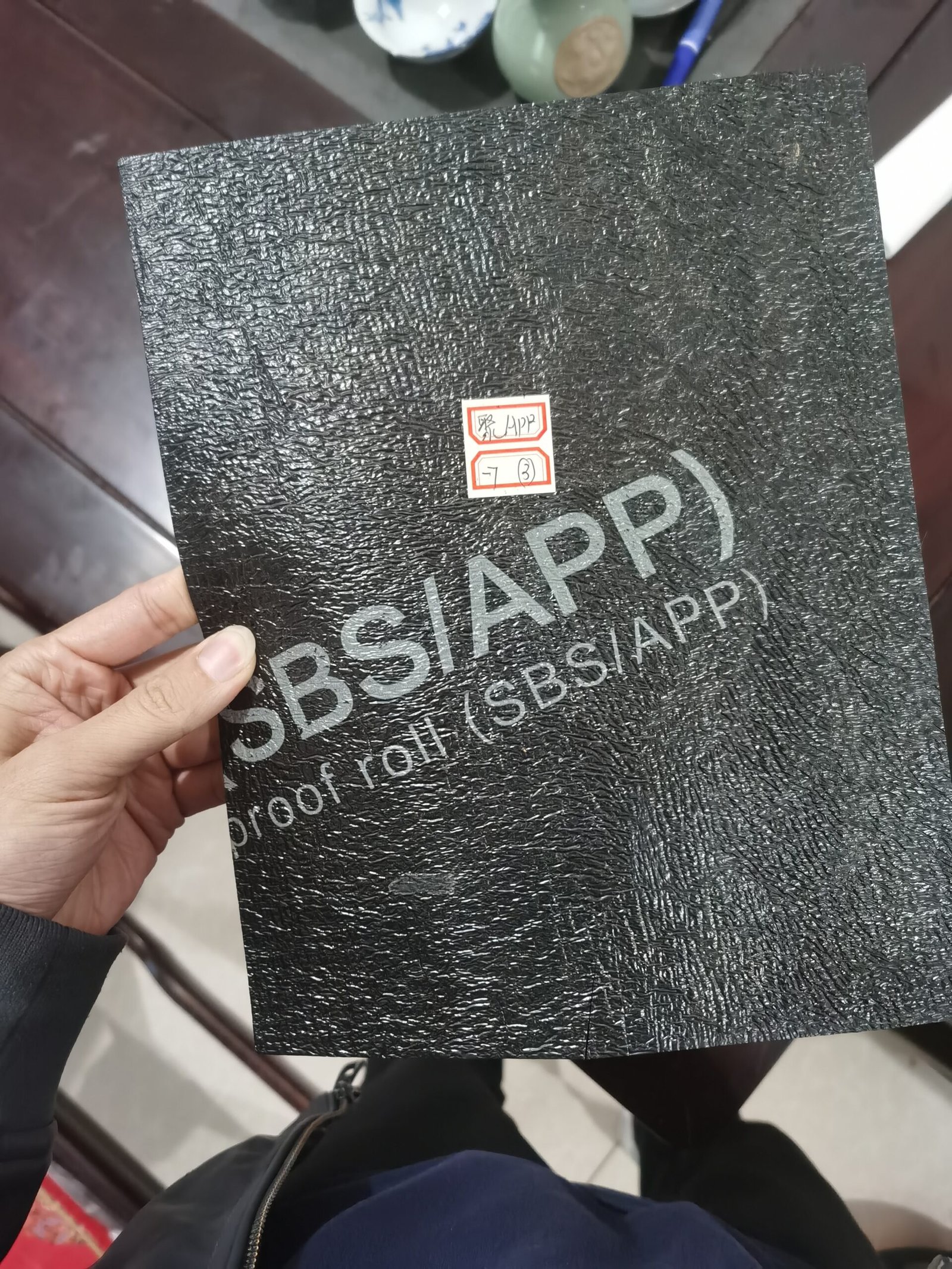

The waterproofing membrane is applied over a substrate that acts as the foundational surface. Common substrate materials include metals, plywood, concrete, cement boards, lightweight insulating concrete, and composite base mats. These materials provide structural support and balance moisture transport and bonding with the membrane. Each substrate has unique properties such as moisture retention and compatibility, which significantly influence membrane performance, especially under extreme weather conditions.

2. Compound Base Mat as an Optimal Substrate

A compound base mat is a multi-layered composite material designed to combine the advantages of various substrates, offering enhanced strength, flexibility, and durability. It provides excellent load distribution and resistance to thermal expansion and contraction, reducing membrane stress and preventing cracking or delamination. This makes compound base mats ideal substrates for modern waterproofing systems where longevity and performance are critical.

3. Other Substrate Options: Spunbond Polyester Mat and Polyester Mat

-

Spunbond polyester mats feature uniform fiber distribution and high tensile strength, promoting strong adhesion and stability of the membrane.

-

Polyester mats offer good flexibility and breathability but have comparatively lower mechanical strength, suitable for lighter-duty applications.

4. Key Factors in Substrate Selection

-

Moisture Content and Drying Time: Membranes must never be applied over substrates with high moisture levels. Proper curing and drying of concrete or other substrates prevent blistering, peeling, and delamination.

-

Surface Preparation and Compatibility: Substrate surfaces should be clean, dry, and free of dust, oil, or loose particles to ensure optimal bonding. Some substrates require primers to enhance adhesion.

-

Thermal Movement and Structural Flexibility: Substrates undergo expansion and contraction due to temperature changes. Matching membrane flexibility to substrate movement is essential to avoid stress-related membrane failure.

-

Load Distribution and Structural Integrity: A stable, strong substrate supports external loads and foot traffic, preventing deformation or water pooling that can damage the membrane.

5. Longevity and Maintenance Benefits

Investing in high-quality substrates such as compound base mats reduces the frequency of maintenance and repair cycles. Though initial costs may be higher, the extended lifespan and improved reliability justify the investment, minimizing long-term expenses and system failures.

Conclusion

The waterproofing membrane alone cannot guarantee roofing durability; the choice and preparation of the substrate—especially the use of compound base mats—are fundamental to the system’s success. Understanding substrate-membrane interaction enables contractors and building owners to make informed decisions, achieving enhanced waterproofing performance, reduced maintenance, and long-term protection.

Contact Us

Weifang Guanlong Waterproof Material Co., Ltd.Your reliable partner for high-quality materials and professional support.

📞 Phone/WhatsApp: +86 18263668883

🌐 Website: glwaterproof.com/product/

📧 Email: guanlinguoji@126.com