Introduction

The waterproofing industry is evolving rapidly with the integration of advanced machinery and automation. Among the latest innovations, the fibre cutting machine stands out as a game-changer. Designed for precision and speed, these machines are redefining how waterproofing materials — especially synthetic and fiber-reinforced membranes — are manufactured and prepared.

What is a Fibre Cutting Machine?

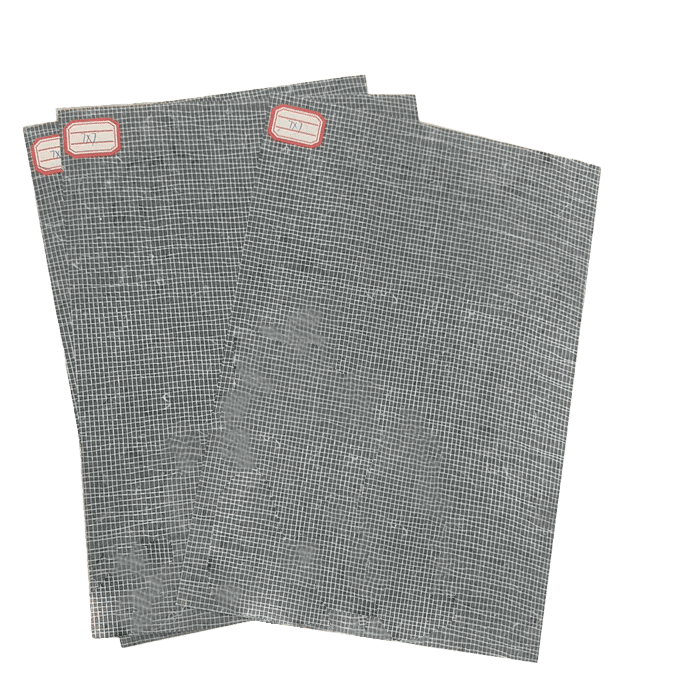

A fibre cutting machine is a specialized device used to cut various types of synthetic and fiber-based materials into precise shapes and sizes. In waterproofing, this includes fiberglass mats, polyester fabric, and composite membranes. The machine ensures consistency and minimizes material waste.

Key Benefits in Waterproofing Applications

-

Precision Cutting

Accurate dimensions are critical in waterproofing to prevent leaks. Fibre cutting machines ensure clean, uniform cuts that improve membrane performance and reduce installation errors. -

Increased Production Efficiency

Automated cutting drastically reduces manual labor and speeds up production lines, especially for large-scale membrane manufacturers. -

Customization & Flexibility

Whether you’re working on flat roofing, tunnels, basements, or balconies, fibre cutting machines can be programmed for different shapes and patterns, enabling tailored solutions. -

Material Optimization

Minimizing waste is both cost-effective and environmentally friendly. These machines optimize sheet usage, reducing scrap rates significantly.

Real-World Applications

Leading waterproofing manufacturers have adopted fibre cutting machines in their production lines for cutting fiberglass backing in bituminous membranes and synthetic polymer membranes. The result? Improved quality, faster production, and fewer failures on-site.

Conclusion

As demand for high-performance waterproofing systems increases, fibre cutting machines are becoming indispensable. Investing in this technology isn’t just a step forward — it’s a leap toward quality, efficiency, and sustainability.