Introduction

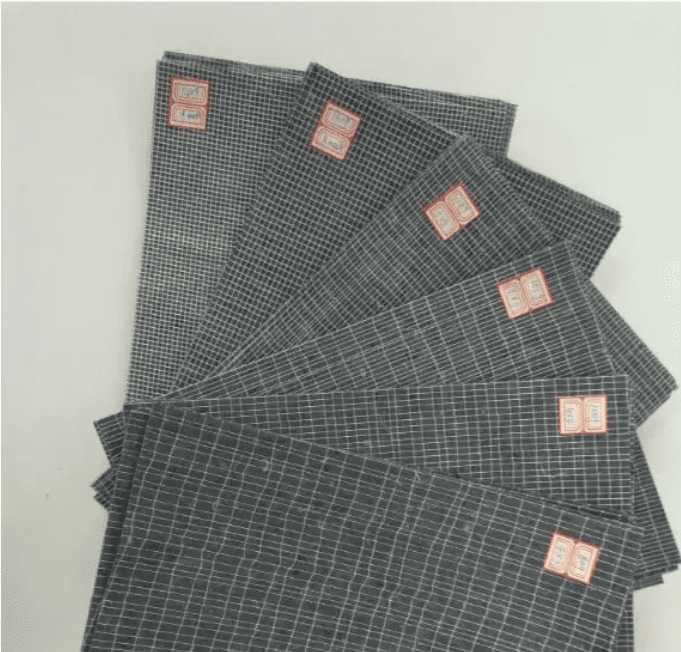

Due to its unique strength and corrosion resistance along with a remarkable long-term durability, the fiberglass compound base mat has emerged as a modern waterproofing solution in construction, infrastructure, and industrial activities. This item’s composition consists of composites that include fiberglass reinforcement along with polymer resin asphalt, polyester, or epoxy. This mixture forms a robust yet pliable waterproofing membrane that is appropriate for roofs, basements, tunnels, and so on.

1. Key Properties for Waterproofing

Fiberglass waterproofing mats are extensively employed in waterproofing because of their peculiar properties:

- High Tensile Strength: Is resistant to cracking and tearing while under a great amount of pressure, even with movement from a structure.

- Chemical Resistance: Can endure acids, alkalis, as well as salts which makes it useful in industrial conditions.

- Low Water Absorption: Has a tight fiber structure with minimum gaps, thus no moisture can penetrate.

- UV & Weather Resistance: Does well in outer applications with no chances of degradation.

- Flexibility & Adaptability: Can be applied to complex surfaces such as pipes and corners seamlessly.

2. Waterproofing Applications

(1) Roofing Systems

- Used as a reinforcement layer in asphalt waterproofing membranes for enhanced durability.

- Acts as a backing material for single-ply roofing (TPO, PVC, EPDM).

(2) Below-Grade Waterproofing

- Protects basements, tunnels, and subways from water infiltration.

- Combined with liquid-applied coatings (polyurethane, acrylic) for a seamless barrier.

(3) Water & Chemical Containment

- Liners for swimming pools, water tanks, and sewage treatment plants.

- Used in bridge decks and expansion joints to prevent water damage.

(4) Industrial Waterproofing

- Prevents leaks in chemical storage tanks, factory floors, and food processing plants.

- Provides moisture protection in cold storage and grain silos.

3. Installation Methods

Fiberglass compound base mat can be installed using different techniques:

(1) Torch-On (Heat Welding) Method

- The mat is heated with a torch to bond with the substrate (common in asphalt-based systems).

(2) Cold Adhesive Application

- Applied using self-adhesive or solvent-based adhesives (for polymer-modified bitumen membranes).

(3) Liquid Waterproofing + Reinforcement

- A liquid membrane (e.g., polyurethane) is applied, followed by embedding the fiberglass mat for added strength.

Critical Installation Tips

Surface Preparation – Must be clean, dry, and free of loose particles.

Overlap & Sealing – Minimum 10cm overlap, sealed properly at joints.

Weather Conditions – Avoid installation in rain or temperatures below 5°C (41°F).

4. Market Trends & Future Innovations

- Eco-Friendly Solutions – Recyclable fiberglass and low-VOC resins for sustainable construction.

- Self-Healing Technology – Smart materials that auto-repair minor cracks upon water exposure.

- Prefabricated Systems – Factory-made waterproofing assemblies for faster installation.

Conclusion

Fiberglass compound base mat is a high-performance waterproofing solution for roofs, underground structures, and industrial facilities. Its strength, flexibility, and chemical resistance make it a preferred choice for long-lasting protection. As technology advances, it will continue to evolve with smarter, greener waterproofing innovations.

Contact Us

Email: guanlinguoji@126.com

Phone/WhatsApp: +86 18263668883

For more Enterprise Products, visit: glwaterproof.com/product/