Introduction

Cotton opening machine play a vital role in the textile industry by preparing raw cotton fibers for further processing. Efficient cotton opening improves fiber quality, reduces impurities, and increases production speed, making these machines indispensable for textile manufacturers.

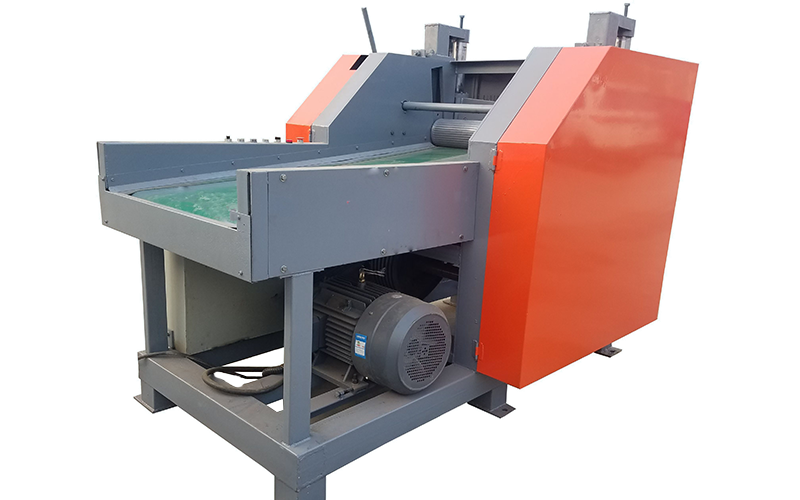

What is a Cotton Opening Machine?

A cotton opening machine loosens and cleans raw cotton fibers by removing dirt, seeds, and other impurities. It prepares the cotton for subsequent stages like carding and spinning.

Key Features

-

Efficient Fiber Opening: Effectively separates cotton fibers for uniformity.

-

Dust Removal: Cleans fibers to improve final product quality.

-

Adjustable Settings: Suitable for different cotton grades and qualities.

-

Durable Construction: Built to withstand continuous industrial use.

Types of Cotton Opening Machines

-

Single Roll Opener

-

Double Roll Opener

-

Fully Automated Machines

Benefits to the Textile Industry

-

Improves fiber quality and consistency

-

Enhances production efficiency

-

Reduces manual labor and operational costs

Maintenance and Operation Tips

-

Clean machine regularly to prevent clogging

-

Lubricate moving parts to avoid wear

-

Follow safety guidelines during operation

How to Choose the Right Machine

Consider production capacity, cotton type, budget, and after-sales support.

Conclusion

Cotton opening machines are essential for efficient and high-quality textile manufacturing. Choose the right machine to boost your production and product quality.

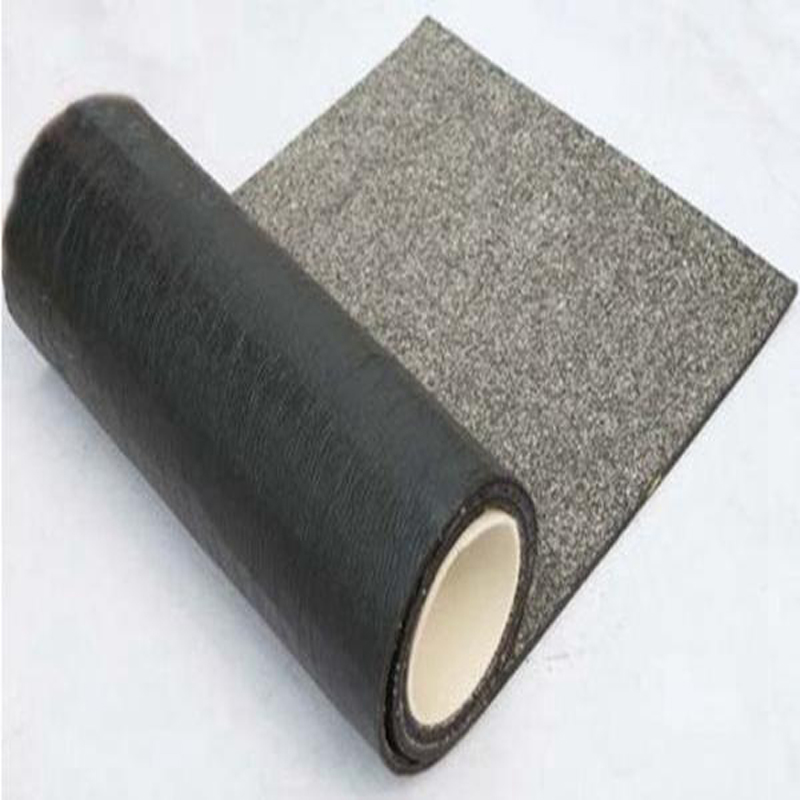

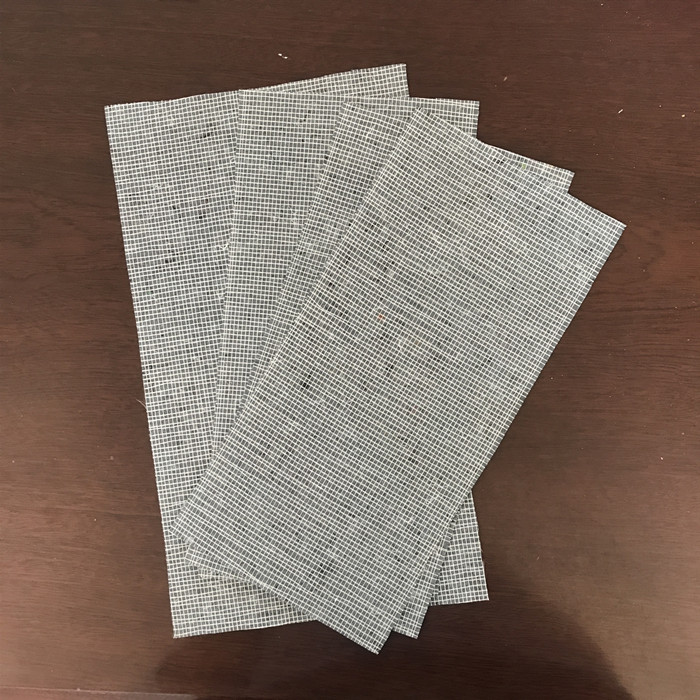

Whether you’re sourcing for infrastructure projects, residential buildings, or industrial roofs, Weifang Guanlong Waterproof Materials Co., Ltd. is your trusted partner for quality bitumen felt and competitive pricing. Contact our team today for the latest catalog, free samples, or a custom quote.

Email: guanlinguoji@126.com

Phone/WhatsApp: +86 18263668883

For more Enterprise Products, visit: glwaterproof.com/product/