The manufacturing of compound base mats, which are used in a wide range of industries including construction, automotive, and textiles, requires precision and efficiency. These mats serve as critical components in many systems, offering support, protection, and stability. Optimizing the production process of compound base mats can significantly enhance productivity, reduce costs, and improve product quality. Here are some strategies for optimizing your compound base mat production line.

Understanding Compound Base Mats

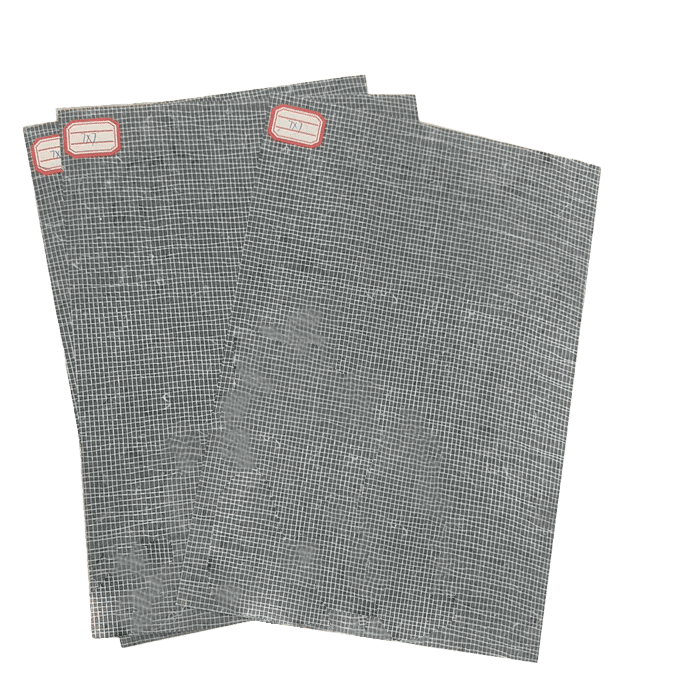

A compound base mat is typically a multi-layered material made from various fibers, including fiberglass, polyester, or a combination of other materials. These mats are often used as a substrate in waterproof membranes, insulation materials, or as reinforcement in composite materials. The production of compound base mats involves several stages, including the preparation of raw materials, the blending of fibers, and the final shaping and curing processes.

Optimizing the Raw Material Selection

The quality of the final product starts with the selection of raw materials. Choosing the right fibers—whether it’s fiberglass, polyester, or a combination—depends on the specific application and performance requirements. Optimizing the raw material selection process can greatly influence the overall quality of the compound base mat.

-

High-Quality Fibers: Ensure that only high-quality fibers are used to ensure strength and durability. Low-grade fibers can lead to defects in the final product.

-

Proper Fiber Blending: The blending process must be optimized to ensure uniformity in the material’s composition. Uneven blending can result in weak spots in the compound base mat, which can lead to structural failure.

Automation in the Production Line

One of the most effective ways to optimize the production process is through automation. Modern compound base mat production lines are equipped with automated systems that streamline the entire process—from fiber feeding to the final curing stage.

-

Automated Fiber Feeding: By using automated fiber feeding systems, you can ensure consistent input of materials, reducing human error and improving the accuracy of the final product.

-

Precision in Layering: Automated systems can accurately control the layering process, ensuring that each layer of the compound base mat is uniform and meets the desired specifications.

-

Advanced Curing Technologies: Curing is a critical step in the production of compound base mats. Automated curing ovens and presses can ensure that the mats are properly cured, achieving the necessary strength and flexibility.

Energy Efficiency

Energy costs can significantly impact the profitability of a compound base mat production line. Optimizing energy consumption should be a priority to reduce overhead costs. This can be achieved through:

-

Heat Recovery Systems: Install heat recovery systems to reuse excess heat in the curing process, reducing energy consumption.

-

Efficient Equipment: Invest in energy-efficient machinery that reduces electricity usage during production, which can lower overall operational costs.

Quality Control and Testing

Consistent product quality is essential to meet customer expectations and industry standards. Incorporating automated quality control systems throughout the production line can help identify defects early in the process.

-

Real-Time Monitoring: Implement real-time monitoring systems that track temperature, pressure, and material consistency throughout the production process.

-

Testing Stations: Set up in-line testing stations to check for critical parameters such as strength, durability, and flexibility of the compound base mats.

Maintenance and Downtime Reduction

Maintaining your equipment is key to minimizing downtime and maximizing productivity. A proactive maintenance schedule can ensure that your machines are running at optimal efficiency.

-

Predictive Maintenance: Use sensors and monitoring systems to predict when equipment is likely to fail, allowing for timely maintenance without disrupting the production flow.

-

Regular Inspections: Conduct regular inspections of key machinery, such as curing ovens and presses, to ensure they are functioning properly and to identify potential issues before they cause a breakdown.

Conclusion

Optimizing the compound base mat production line is a multifaceted process that involves careful attention to raw material selection, automation, energy efficiency, quality control, and maintenance. By implementing these strategies, manufacturers can improve the overall efficiency of their production lines, reduce costs, and produce high-quality compound base mats that meet industry standards. Whether you’re looking to scale up production or improve product quality, a well-optimized production line is key to staying competitive in the market.