What Is a Compound Base Mat?

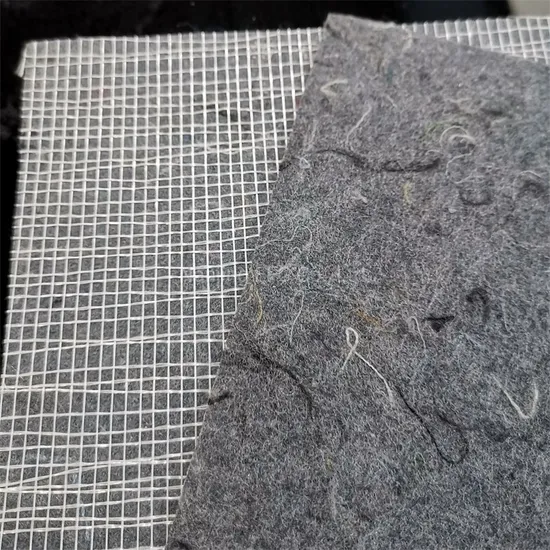

A compound base mat is formed by molding several base layers together, foam non-woven fabrics or mats made of polyester and glass fiber, and usually set with bitumen, polymers, or asphalt for enhanced waterproofing properties.

The “compound” part refers to its layered structure which is balanced to tackle tensile seizing, warping, dimensional control, and absorption fortification makes it suitable as a multi-layer composite reinforcement for the waterproofing membrane.

How Compound Base Mats Are Used in Waterproofing

Compound base mats are primarily used as reinforcement carriers for various waterproofing membranes, including:

-

Modified bitumen membranes (SBS/APP)

-

Self-adhesive membranes

-

Liquid-applied membranes (LAM)

-

Composite waterproofing sheets

They serve several key functions:

-

Dimensional Stability: Reduces deformation during heating or under mechanical stress.

-

Reinforcement: Enhances tensile strength and puncture resistance.

-

Compatibility: Works well with a variety of waterproofing compounds.

-

Ease of Application: Facilitates uniform coating during production and simplifies onsite installation.

Application Process:

Workers typically saturate or coat the mat with bitumen or a polymer-modified compound.

Workers then roll it onto the surface as part of a layered membrane system.

For self-adhesive systems, installers remove a peel-off layer during installation.

Performance Comparison: Compound Base Mat vs. Traditional Mats

Let’s compare compound base mats with traditional single-material base mats such as pure polyester, fiberglass, and non-woven fabrics.

| Feature | Compound Base Mat | Polyester Mat | Fiberglass Mat |

|---|---|---|---|

| Tensile Strength | High | Moderate | High |

| Dimensional Stability | Excellent | Moderate | Excellent |

| Puncture Resistance | Strong (multi-layer) | High | Low |

| Water Absorption | Low | Moderate | Low |

| Heat Resistance | High | Moderate | High |

| Cost | Moderate to High | Moderate | Low |

| Recommended Use | High-performance systems | Residential waterproofing | Industrial roofing |

Advantages of Compound Base Mats

-

Enhanced Performance: The multi-layer design allows for customization, offering a perfect balance between strength and flexibility.

-

Longer Lifespan: Compound base mats extend the durability of the membrane, reducing maintenance.

-

Versatile Compatibility: Suitable for both cold and hot-applied systems.

-

Improved Adhesion: Offers better bonding to bitumen and polymer-based compounds.

Final Thoughts

While traditional materials like fiberglass and polyester mats still play important roles in waterproofing systems, compound base mats offer a significant upgrade in terms of performance and durability. Their use is especially recommended for projects requiring long-lasting protection, such as commercial roofing, bridges, and tunnels.

For engineers, architects, and contractors looking to improve waterproofing reliability, compound base mats are proving to be a smart investment.

Contact Us

Weifang Guanlong Waterproof Material Co., Ltd.Your reliable partner for high-quality materials and professional support.

📞 Phone/WhatsApp: +86 18263668883

🌐 Website: glwaterproof.com/product/

📧 Email: guanlinguoji@126.com