People usually employ bitumen felt base mats for waterproofing and roofing purposes. Here’s an FAQ guide covering some critical parts:

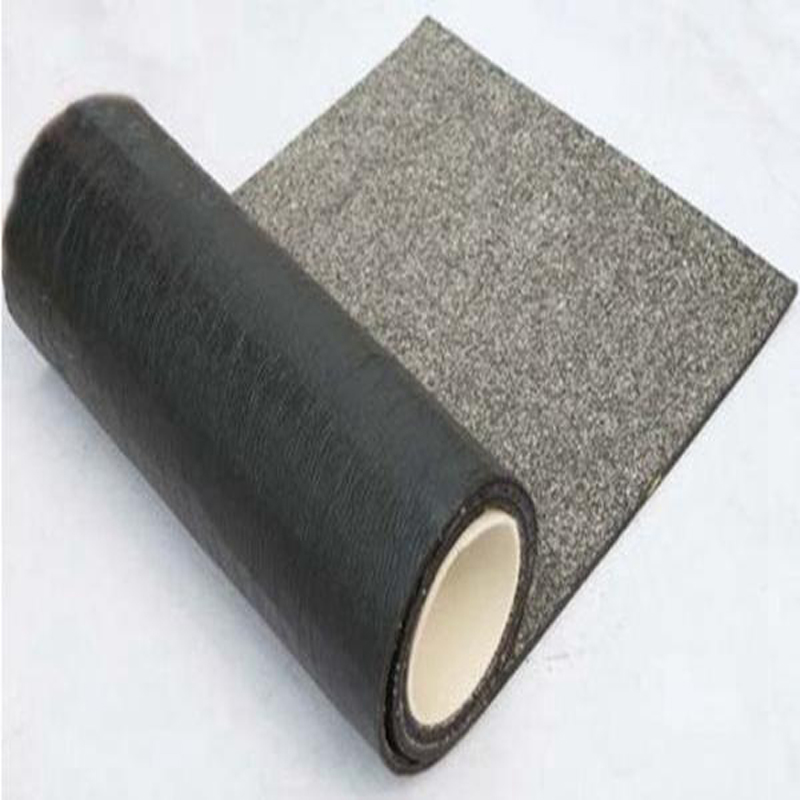

1. What is bitumen felt base mat?

Bitumen felt base mat (also called underlayment) serves as a waterproofing membrane in roofing systems. Its base layer consists of either reinforced or non-reinforced bituminous felt. Manufacturers produce it by saturating or coating a host material—such as polyester mat, fiberglass, or organic felt—with bitumen, asphalt, or modified bitumen.

2. What are the types of bitumen felt base mats?

- Felt with Reinforcement:Used for greater strength due to fiberglass or polyester reinforcements.

- Non-reinforcement (Organic Felt): Made from cellulose fibers. Not very durable, but more elastic

- Torch-On Felt: Requires heat (flame) for installation.

- Self-Adhesive Felt: Has a peel-and-stick backing for easier application.

- Perforated Felt: Allows trapped moisture to escape (used in certain roofing systems).

3. What are the main applications?

- Roofing underlayment: Provides a waterproof barrier beneath shingles, tiles, or metal roofing.

- Damp-proofing: Used in foundations or below-grade structures.

- Flat roof systems: As a base layer in built-up roofing (BUR) or modified bitumen systems.

4. What are the advantages?

- Waterproof: Acts as a moisture barrier.

- Flexible: Adapts to minor substrate movements.

- Cost-effective: Affordable compared to other waterproofing membranes.

- Durable: Resists UV (if covered) and weathering.

5. How is it installed?

- Surface Preparation: Clean, dry, and smooth the substrate.

- Adhesion Methods:

- Torch-applied: Heated with a flame for bonding.

- Cold-applied: Using bitumen adhesive or self-adhesive backing.

- Mechanical Fixing: Nails or staples (for temporary underlayment).

- Overlap: Sheets should overlap (typically 100mm side/end laps) for watertightness.

6. What are the key standards?

- BS 8217: British Standard for reinforced bitumen membranes.

- EN 13707: European standard for reinforced roofing felt.

- ASTM D226/D227: US standards for asphalt-saturated felt.

7. How long does bitumen felt last?

- Base layer (underlayment): 10–20 years, depending on exposure.

- Exposed roofing: 5–15 years (requires protective top layers).

8. Can it be repaired?

You can patch damaged sections with bitumen tape, liquid bitumen, or a new felt layer.

9. What are common issues?

- Blistering: Trapped moisture or poor adhesion.

- Cracking: Aging or extreme temperature changes.

- Poor adhesion: Incorrect installation or dirty substrate.

10. Is bitumen felt environmentally friendly?

- Manufacturers produce traditional bitumen from petroleum, but some modified versions use recycled materials.

- Alternatives like synthetic underlayment (TPO, EPDM) are more eco-friendly.

11. Can it be used with other roofing materials?

Yes, it works under:

- Asphalt shingles

- Metal roofing

- Slate/tiles (as a secondary barrier)

12. How does it compare to synthetic underlayment?

| Feature | Bitumen Felt | Synthetic (e.g., Polypropylene) |

|---|---|---|

| Weight | Heavier | Lighter |

| Durability | Moderate | Higher tear resistance |

| Waterproofing | Good | Excellent |

| Cost | Lower | Higher |

Would you like more details on a specific aspect (installation, brands, etc.)?

Contact Us

Email: guanlinguoji@126.com

Phone/WhatsApp: +86 18263668883

For more Enterprise Products, visit: glwaterproof.com/product/