Introduction

Waterproof compound mats are advanced engineered materials designed to provide superior moisture resistance, durability, and flexibility. Composed of multiple layers of synthetic polymers, fibers, and additives, these mats are widely used in construction, automotive, and industrial sectors. This article explores their composition, key properties, and applications.

1. Composition

Waterproof compound mats typically consist of:

-

Base Layer: Polyethylene (PE), polyvinyl chloride (PVC), or thermoplastic polyolefin (TPO) for waterproofing.

-

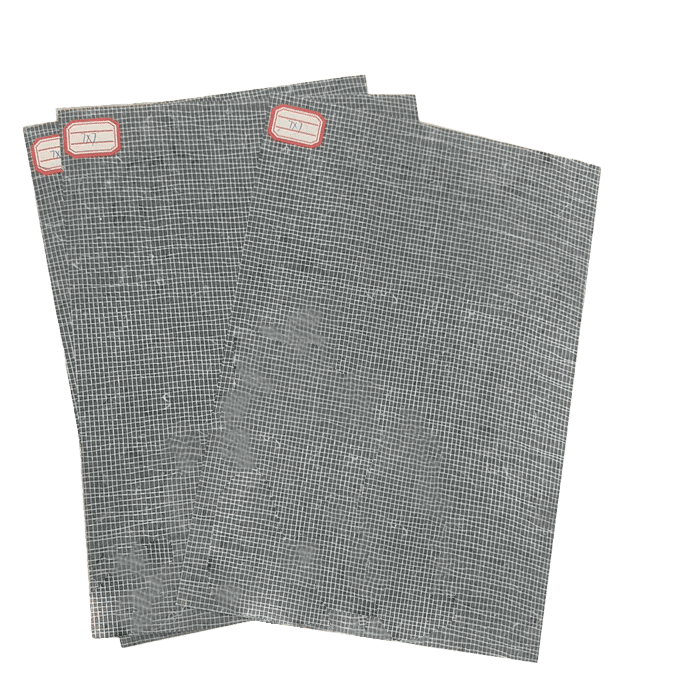

Reinforcement Layer: Fiberglass or polyester mesh for tensile strength.

-

Adhesive Layer: Bitumen or acrylic-based compounds for bonding.

-

Surface Treatment: UV-resistant coatings or textured finishes for added protection.

2. Key Properties

-

Water Impermeability: Prevents water penetration even under high pressure.

-

Chemical Resistance: Resists oils, acids, and alkalis.

-

Thermal Stability: Performs in temperatures ranging from -30°C to 80°C.

-

Eco-Friendly Options: Some mats incorporate recycled materials.

3. Applications

-

Construction: Roofing, foundation membranes, and tunnel linings.

-

Automotive: Flooring and trunk mats.

-

Landscaping: Pond liners and garden drainage systems.

Conclusion

With their customizable layers and robust performance, waterproof compound mats address diverse industry needs. Ongoing R&D focuses on sustainability and cost-efficiency, further expanding their utility.