Introduction

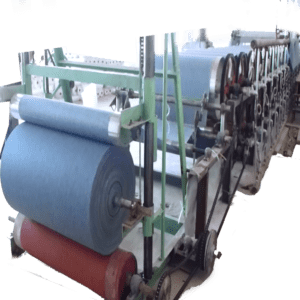

Waterproof materials are essential for the construction and roofing field. To ensure effective waterproofing, manufacturers apply state-of-the-art compound base mat production line which construct base mats for roofing and waterproofing. These systems guarantee uniform quality and optimal productivity.

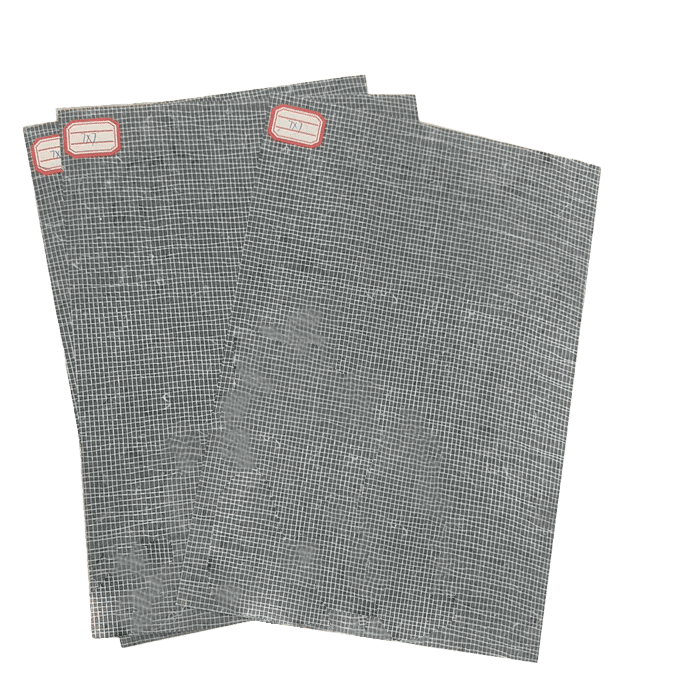

What is a Compound Base Mat?

A compound base mat is defined as fiberglass, polyester, or reinforcing elements encapsulated with bitumen or polymer-modified compounds. It is used as a basis in roofing membranes as it is multi-layered to be robust, flexible, and resistant to water.

The Production Process

A line dedicated to compound base mat production has the following processes:

- Material Preparation – Workers feed raw materials like fiberglass or polyester into the production line.

- Impregnation – The system saturates the base material with bitumen or polymer-modified asphalt for waterproofing.

- Drying & Cooling – The coated mat moves through drying ovens to remove moisture before cooling stabilizes the material.

- Surface Treatment – Operators may add mineral granules or protective films for UV resistance.

- Cutting & Rolling – The production line cuts the final product into rolls for easy transport and installation.

Benefits of Modern compound base mat production line

- High Efficiency – Automated systems speed up production while maintaining consistency.

- Superior Quality Control – Precise coating and drying processes improve performance.

- Customization – Factories can adjust formulations to meet specific waterproofing needs.

Conclusion

production line is essential in the waterproofing products industry for efficient and reliable waterproofing materials. Industrial equipment meets producer requirements while maintaining standards.

Contact Us

📧 Email: guanlinguoji@126.com

📞 Phone/WhatsApp: +86 18263668883

For more Enterprise Products, visit: glwaterproof.com/product/