Description

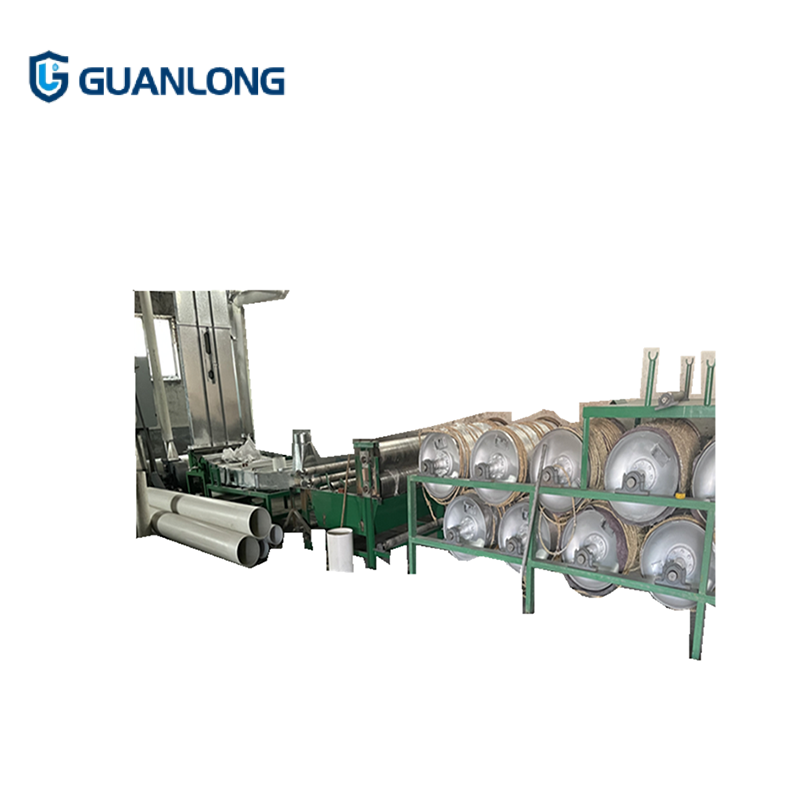

The working principle can be divided into 4 steps.

- To paving the fluff cotton fiber on the production beginning by pipelines.

- Dip coat the cotton layer by starch .

- Combine the fiberglass mesh and cotton layer together.

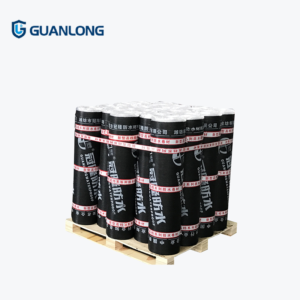

- Drying the combined mat and cutting edges to get the ready rolls.

- Scale of production:

According to the product broadband 1 meter, product specifications 3X3、4X4、5X5、6X6、7X7,Working 24 hours a day, production of compound mat per day 50000 meters.

- Raw material:

Denim cotton percentage>70%,A cotton fiber with a length of about 20mm.

- Dip gluematerial:

Food starch (preferably corn starch).

Reinforced fiberglass mesh material:

Specification:3X3、4X4、5X5、6X6、7X7

- Product specification:

The width is 1 meter, and the specifications are divided into 3X3, 4X4, 5X5, 6X6 and 7X7 according to the glass fiber mesh specifications.

- Line speed:

0-30m/min

- Installed power:

Total installed power of the production line: 47.5KW(excluding boiler power).

- Main workshop size:

(length > 26)×(width > 8)×(height > 5)m

- Artificial requirements:

The whole production line should be equipped with 3 operators (excluding boiler workers and Technician worker).

Male worker :1 person (age < 50)

Worker :3 (age < 50)

- Publicworks:

Power consumption: The whole production line adopts three-phase and four-wire alternating current,380V/220V,50Hz。

Water for glue production: 24 hours water consumption:12Ton.

Steam boiler: recommended 1 ton/h。

Steam pressure:0.3-0.4Mpa

Attached figure: process flow chart of compound mat production: